Most of us know how damaging the harsh rays of the sun can be on all kinds of surfaces – from our lawns to our wooden structures and even our own skin. But you may not know that sun can also damage concrete surfaces. As strong and durable as concrete is, even pavement is not invincible when it comes to the damage done by harmful UV rays. That is particularly true in the heat of the summer.

How the Summer Sun Damages Concrete

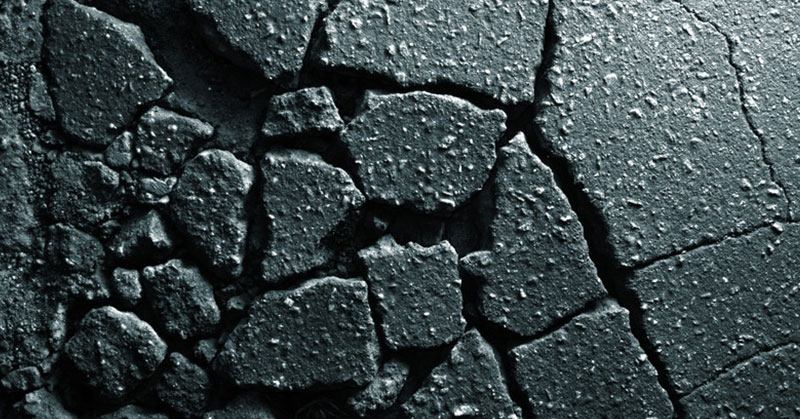

When it comes to an existing concrete surface, the sun’s UV rays can cause a wide range of damage depending on how many hours the surface is exposed to bright sunshine on a daily basis. The UV rays actually destroy the polymers of the concrete, and over time bright sunshine can significantly weaken and disintegrate the pavement. This damage ranges from cracking and separation between the pavement and the seams in the concrete to fading of colored concrete and an increasingly brittle surface. Eventually, concrete that is badly damaged by the sun will quite literally turn to dust.

Bright sunshine can also have a negative impact on freshly poured concrete surfaces. If you attempt to install concrete in bright sunshine and too-hot temperatures, water in the pavement will evaporate too quickly, weakening the concrete and causing it to crack and shrink.

How to Protect Your Concrete Surface from the Sun

Ideally, your pavement would not be exposed to bright sunshine all day long every day. That’s one of the many reasons why it’s helpful to build a cover over a concrete patio or driveway, for example. But for many surfaces – such as parking lots and roadways, for example – it’s simply not possible to cover your pavement. One of the best ways to protect your concrete surface is with a high quality sealer that includes UV-blocking ingredients. It’s also important to have any damage repaired right away to prevent the surface from deteriorating any further.

If your concrete is freshly poured, you can protect it from sun damage by keeping it wet and covered with a film or tarp during the curing process. Anything you can do to protect the freshly installed surface from the weather while it’s curing will help to create the strongest pavement possible. The paving contractors who install your new surface will be able to provide helpful suggestions on how to protect your new surface.

For more information about how sun can damage concrete, and how to protect your paved surfaces, contact a local reputable concrete paving specialist.